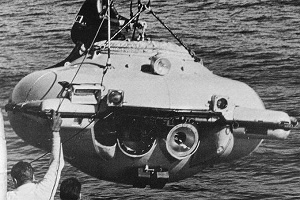

When I was a kid, I was always fascinated with the Undersea World of Jacques Cousteau. The technology they developed to go deep into the ocean was amazing. I once heard James Cameron speak at SOLIDWORKS World and he discussed his innovations to allow for the exploration and salvage of the Titanic. He also spoke of new technology that would allow vehicles to fully explore the Mariana Trench, the deepest known part of the world's oceans (and that would obviously be the deepest dive ever). The term "deep dive" has also become synonymous with a thorough review of technologies. We use it often to indicate a meticulous breakdown of a particular subject matter. Obviously, in the context of the discussions I began previously on engineering-based PLM and manufacturing-based PLM, a "deep dive" would indicate a breakdown of the characteristics of the two PLM technologies and the benefits and shortcomings of each approach. Before we embark on our voyage on our own virtual Calypso (Jacques' boat), I wanted to outline the approach we will take to analyze each PLM platform.

While there are a number of worthy candidates from a Product Lifecycle Management (PLM) perspective, in order to keep this article series relatively concise, we will need to tag specific PLM solutions to be representative of each approach. Based on our experience, there seem to be two PLM solutions that effectively represent the engineering-based PLM platform. PTC's Windchill PDMLink and Siemens' Teamcenter are widely adopted solutions particularly in the Aerospace and Defense segments as well as Heavy Equipment Industry, and both are dominated by engineering concerns. We (Zero Wait-State) also have firsthand experience with both of these applications, which helps in providing accurate analysis of the characteristics of these applications. PDMLink excels at managing data generated from their computer aided design (CAD) solution Pro/E and Teamcenter leverages NX CAD data equally well. These CAD integrations are the linchpin for the value of these solutions and very rarely do customers adopt these applications without owning the CAD products associated with these PLM applications. For the manufacturing-based PLM solutions, we have identified Oracle's Agile PLM and Dassault's Matrix One (remember, this is a TBT article originally written in 2010). Both of these applications were standalone PLM solutions at one time and have been acquired. As standalone PLM solutions, they tended to concentrate on the bill of material (BOM) creation and management aspects as well as downstream supply chain issues. Both of these products tended to minimize engineering's participation in the PLM process and concentrate more heavily on providing accurate information to companies' enterprise resource planning (ERP) tools. While both PDMlink and Teamcenter have respectable market share in the high-tech space, certain types of companies in this sector tend to gravitate toward solutions like Agile and Matrix One. Again, there are other solutions that compete with these products, but for our purposes they represent the typical characteristics of the manufacturing-based PLM due to their evolution as standalone PLM vendors and the markets they tend to serve.

There are a number of ways one could go about analyzing these solutions, but to illustrate the points we are trying to highlight about the inherent strengths and weaknesses of these applications, we looked at four specific areas. The first article reviewed the data models of each platform. There are consistent similarities between PDMLink and Teamcenter due to their origins and client base and also with Agile and Matrix. We first highlighted how this model looked and what the implications behind the model were for clients. The second article (two parts) focused on user experience. Again, because of the background of the solutions and how they are utilized, the user interfaces are somewhat different for each platform. We looked at what this meant for clients and highlighted the different approaches. The third article discussed work in process management: how each platform handled managing the CAD data generated by authoring tools like Pro/E, NX, SOLIDWORKS, Mentor, Cadence, etc. As with the other articles, there were clear differences in philosophy about this information and it affects the overall architecture of the applications significantly, which can be a real issue for potential clients.

So get ready, check your tanks...and we are off to explore the depths of PLM!

Speaking of exploration, you'd be a better diver if you took additional SCUBA classes, right? This same thinking holds true for your PLM system. Our first online training program, Integrating Mechanical Design into PLM, just launched and we’ve opened registration for the first class, Introduction to CAD Integration, at NO COST. Seating is limited to make sure all students have access to our expert trainers. Don’t miss this opportunity!

[Edited and re-posted from 2010]