To continue the thoughts around effective utilization of technology, I want to share some data gleaned from out last webinar, which was an introduction to our upcoming online training for engineering collaboration for Oracle’s AgilePLM. In the first blog of our “All Dressed Up and Nowhere to Go” series, we highlighted the value of training and how it is often neglected when companies purchase PLM. In the second article, we emphasized the importance of having a sound base established with PLM before embarking on the latest trendy initiatives like Innovation Management or Internet of Things (IoT). This article will focus on taking advantage of the functionality you already own and how often technology is underutilized by the companies that purchase it.

I have worked with numerous product development organizations over the years and rarely have I encountered a company that had fully leveraged their investments in process-oriented software like Product Lifecycle Management (PLM) or even computer aided design (CAD). Most companies struggle with adoption of even basic functions of software, which was what triggered the first article in this series. The answers we received to our polling questions in our last webinar tend to validate this idea. Granted, the numbers of respondents is not statistically significant, but I suspect if we expanded the numbers they would track in a similar fashion. We had 30 people from 20 different companies attend the webinar and the industries they came from included High Tech, Aerospace, Medical Device and Industrial, so it is a fair representation of discrete manufacturing companies. Almost all of the companies have invested in Agile PLM and the Engineering Collaboration Module since the point of this webinar was to preview some of the training content for improving adoption and usage of this application. I should note some of the responders just recently implemented Engineering Collaboration, but the responses are still telling in regards to taking full advantage of the capabilities offered by the software.

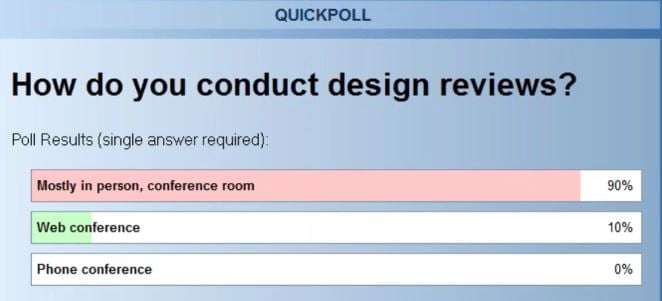

The two training modules we previewed in the webinar were focused on virtual design reviews and the use of CAD model thumbnail representations in PLM. The results of the survey did not surprise us because we knew when we selected these two topics for the event that both are underutilized by our clients, and I suspect, in the PLM industry period. The first question was “How Do You Conduct Design Reviews?”. Ninety percent of the responders conduct design reviews in person in a conference room.

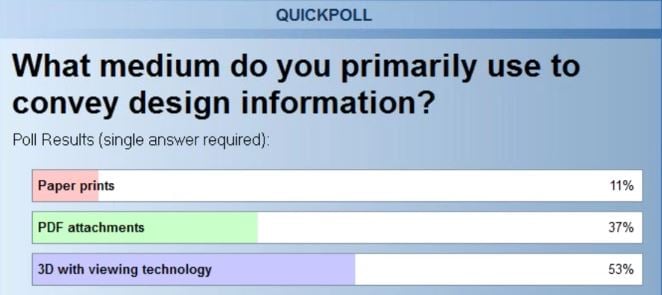

We also learned that over half of them us 3D models to convey design information.

So the interesting thing about these two poll questions is that while these companies have the means to conduct virtual design reviews, they choose to execute this function in a very traditional time-and-resource-intensive way. I am sure some of this is about culture and resistance to change and technology, and some of it could have to do with the organizational structure of companies’ engineering groups, but a properly constructed virtual design review can be far more effective than a traditional face-to-face meeting around the conference table. PLM allows for documentation of input, and the visualization capabilities – regardless of the CAD tool or PLM system – are quite advanced. The takeaway from the poll questions is that it is important to make sure you are taking full advantage of the tools you own and not just following the path of least resistance when it comes to technology adoption.

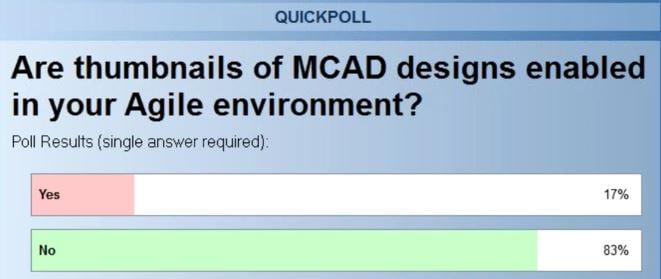

The other set of poll questions included a question about thumbnails and their adoption. Eighty-three percent did not use thumbnails despite having the capability to do so.

This is an interesting phenomenon that we have noticed in most companies owning PLM. Enabling thumbnails can be an engineering centric activity, but the groups that benefit the most from the thumbnails are not typically in Engineering. The engineers have access to CAD tools and are usually very familiar with the data. Groups like manufacturing, purchasing, quality, etc. are the ones that can gain value from seeing graphical representations of the parts in the system. Since the thumbnails have to be enabled by engineering, often these other groups aren’t even aware it is a possibility or just don’t even try to get them turned on. Often thumbnails can create bandwidth issues, so IT is also happy to leave them out of the configuration since it is one less headache for them. The net result is that a time-saving and potentially error-saving capability does not get used.

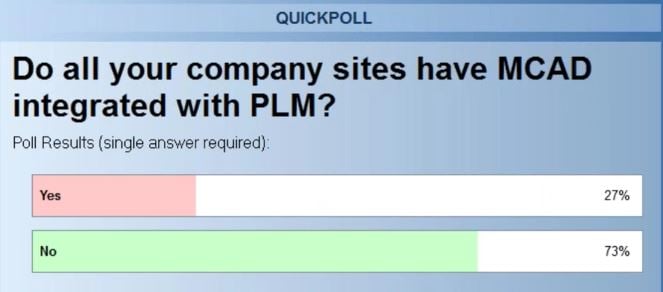

The last to questions were also very revealing in regards to leverage of PLM technology. The first of these questions was, “Do all of your company sites have MCAD integrated with PLM?”. We know across the whole PLM space this number is low, but you would expect with a group coming in for CAD integration training that the numbers would be higher. Seventy-three percent of the responder’s companies are not fully integrated.

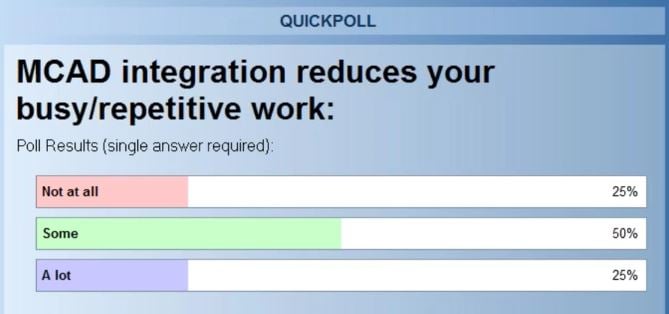

We also asked about the benefit of MCAD integration related to the reduction of repetitive task, and seventy-five percent said it helps some or a lot.

The conclusion that we can draw from this is that there are benefits to integration, but companies are still lagging in getting all groups tied to PLM.

Overall, the data we pulled from the webinar just continues to reinforce what we are seeing in the industry. Investment in new technology is exciting and can enable new capabilities, but there is still enormous value in just enabling and accessing the capabilities you already own before moving on to something new.

As I mentioned above, our first online training class, Introduction to CAD Integration, just finished and we’ve posted the recording for you, on-demand. Click here to watch now!