Just a couple of weeks ago, I was talking to a compliance manager for a prominent company in Silicon Valley, a man I highly respect. To my astonishment, he still did not fully understand the updated definition of an article under the REACH legislation. To jog your memory, in September 2015, The European Court of Justice (ECJ) has clarified their interpretation of the definition of an article by clarifying the scope of the notification and communication obligations under REACH Articles 7(2) and 33 for complex products (products made up of more than 1 article). In my friend’s mind, the article was/is the whole component (in this case an IC) his company buys from suppliers. How wrong he was. In this blog, I will show you the different articles in an IC and how it can easily lead to a company not complying with their REACH obligations.

To help us with this analysis, the European Chemical Agency (ECHA) recently released version 4 of their “Guidance on Requirements for Substances in Articles" document. This document goes into great detail the ramifications of this ECJ interpretation and consequently has flow charts on how to identify articles in a product and how to calculate the concentration of substances in these articles. Since the document does not contain many electronic examples (Hello IPC and other electronics industry groups - there is a definite need by your members for examples for common components!), I decided to write this blog post using the IC example I discussed with my friend.

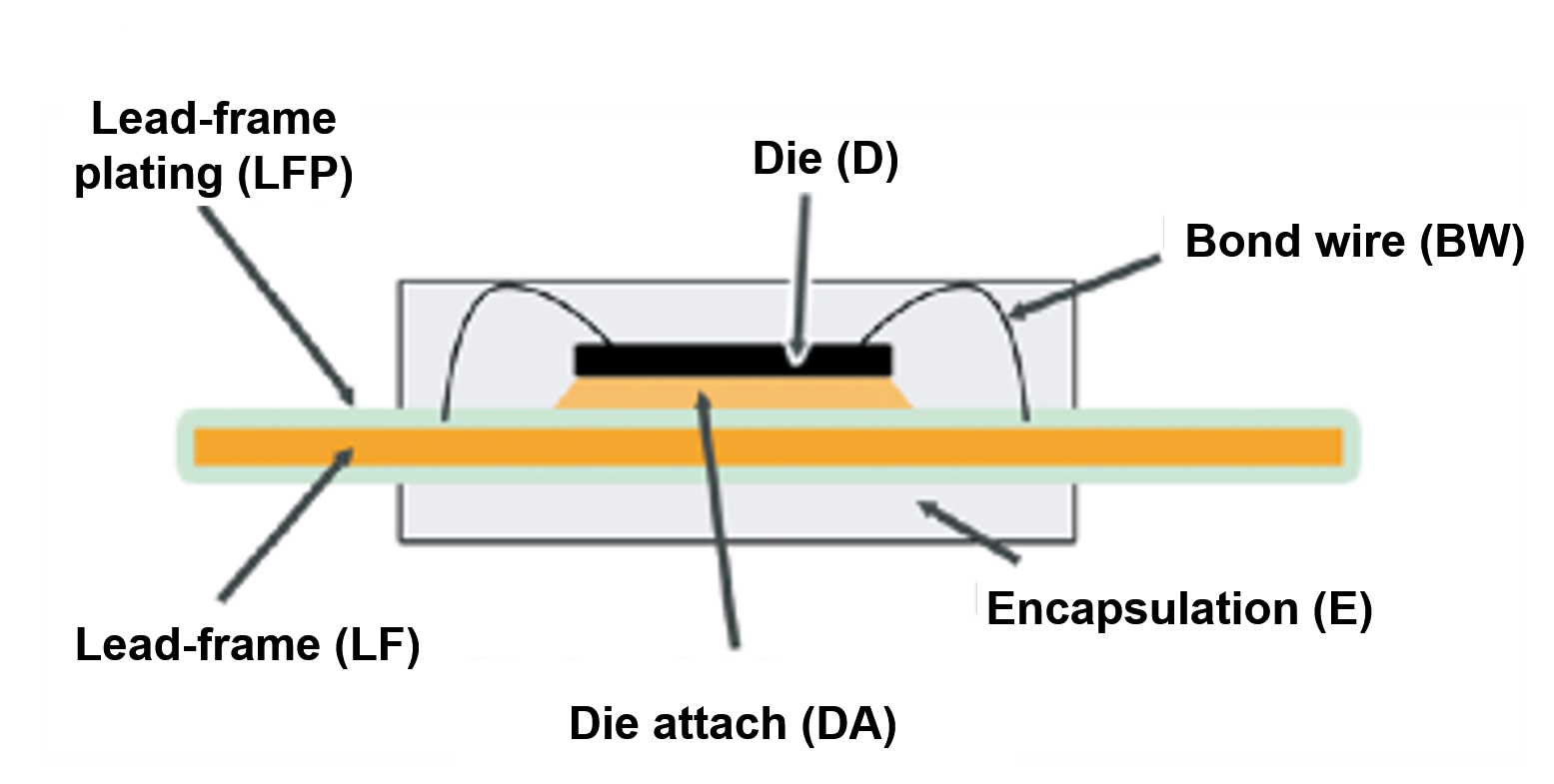

In the remainder of this blog post I will use the following generalized example of an IC for arguments’ sake. The areas pointed at by arrows are the homogeneous materials in the IC as defined under the RoHS directive.

Figure 1: Homogeneous materials in an IC

Figure 1: Homogeneous materials in an IC

REACH Recap for SVHCs in Articles

Anyone familiar with REACH and Substances of Very High Concern (SVHCs) in articles can skip this section. For anyone else here is a quick refresher.

Article 7(2) requires producers and importers of articles in the EU to notify the ECHA of an SVHC in articles if the following 4 conditions are all true:

- the substance is included in the SVHC Candidate List, and

- the substance is present in articles above a 0.1% concentration by weigh of the article, and

- the total amount of the substance present in all articles produced or imported by that producer or importer exceeds 1 tonne per year, and

- exemptions (i.e. exclusion of exposure or already registered for that use) do not apply

Unless you are using SVHCs in a peculiar and unique manner, there typically is no need to worry about this notification requirement. Most SVHCs are already registered for whatever use manufacturers are applying them to, so the need for the vast majority of manufacturers to notify should be extremely rare.

The one to look out for is Article 33.

Article 33 requires communication throughout the supply chain, including consumers, to allow the safe use of articles if:

- the substance is included in the Candidate List, and

- the substance is present in articles above a 0.1% concentration by weight of the article

As you can easily see, the concentrations and resulting requirements are very dependent on the definition of an article. In the IC’s case, the difference between the entire IC, and for instance, the lead frame in the IC.

Once an Article, Always an Article

In short, this is what the opinion of the ECJ boils down to, based on the definition of an article in Article 3(3) of REACH. An article is defined as “an object which during production is given a special shape, surface or design which determines its function to a greater degree than its chemical composition.”

Previously, the consensus was that an article was the final product that was produced or imported into the EU. This made it fairly easy to meet the 0.1% concentration threshold preventing the need to notify and communicate. The weight of a Candidate list substance typically is minuscule compared to the weight of the final product and staying below the 0.1% concentration threshold was easy.

Applied to the IC example, the entire IC was considered the article if the IC itself was imported into the EU. And if a product is imported in the EU containing the IC, then the whole product was the article.

But, notice the “during production” clause. The opinion of the court is that during production of a product, articles can be created and joined into a more complex product and these smaller articles are the ones you must use to validate the 0.1% concentration threshold against. If we apply this to the IC example above, it does not matter whether the IC or a product containing the IC is imported into the EU. During the manufacturing of the IC, articles were created in it; these articles were joined together into the final IC and the articles don’t change.

Concretely what this means is that an article in a component is now something that falls in between a homogeneous material (as defined under RoHS) and the complete component based on the manufacturing process.

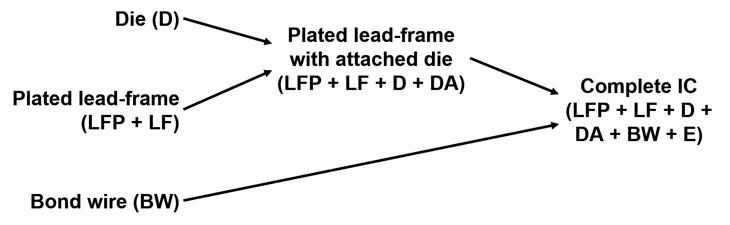

If we look at the generic picture of an IC above (Figure 1), each area indicated with an arrow represents a homogeneous material. Based on the manufacturing steps of the IC and the above definition of an article (special shape, surface or design that defines its function to a greater degree than its chemical composition), the 6 homogeneous materials create the 5 articles in Figure 2 below. Between parentheses, I indicated the homogeneous materials in Figure 1 that make up each of the articles in the chip. The identification of the articles was done based on the flow charts in the Guidance document and even then, I had to validate this with some other experts in the field (thank you Mike Kirschner for your validation and input). Note that the mold compound in the encapsulation and the die attach compound are considered mixtures under REACH.

Figure 2: Articles within an IC and the homogeneous materials (in parentheses) they consist of

Validating the 0.1% Concentration Threshold

Now that we have identified 5 articles in our example, let’s move on to validating the SVHC concentrations against these articles.

For a given SVHC present in one or more of the homogeneous materials in the IC, we need to calculate its total weight in each of the 5 articles across all homogeneous materials making up that article and divide by the weight of the article to get to the SVHC’s concentration in that article.

If that concentration is below 0.1% for each article, then there are no reporting nor notification requirements. If the SVHC surpasses the 0.1% threshold for at least 1 article, then at least the communication requirement is triggered, and possibly but very rarely the notification requirement.

As you can see, the key to all of this is the substances in the homogeneous materials.

What Does this Mean for You and Your Data Collection

First of all, of course you can still ask for REACH Certificates of Compliance (also known as Yes/No declarations) from your suppliers; put your head in the sand; hope your suppliers understand how to identify articles in their product and how to evaluate the REACH status and trust the CoC you receive. This Hope-For-The-Best strategy is a strategy you can pursue and lots of companies are doing just that. It depends on your company’s appetite for risk, maturity, and power over suppliers. However, from a due diligence perspective, this strategy is getting weaker and weaker.

If, on the other hand, you collect substances information including partial or full material disclosures from your supply chain, then you will now need your suppliers to tell you where the articles are in the composition hierarchy or bill of substances of their product based on their manufacturing process. This will cause enormous confusion and consternation for at least the next couple years! Don’t forget: your compliance data collection people and the supplier’s compliance data entry people typically are not manufacturing experts.

My normal advice about data collection changes slightly based on this new situation:

- Get as much as possible full or partial material disclosures. Use REACH certificates if there is no other way.

- For the proprietary substances and materials in material disclosures, get certificates of conformance that these materials do not contain substances on the REACH Candidate list or on a list your company communicates to suppliers.

- Require your suppliers to identify the article levels in the bill of substances they provide to you at the homogeneous material level.

- Evaluate the 0.1% threshold concentration for SVHCs at the homogeneous material level. This is a more conservative approach than the article level validation but it has the advantage that it does not rely on manufacturing knowledge. At this point, homogeneous materials are better understood in the supply chain and by your data collection people.

If an SVHC is below the threshold in a homogeneous material, it is guaranteed to be below the threshold concentration in any article made up of that homogeneous material.

On the other hand, if an SVHC is above the 0.1% threshold concentration in a homogeneous material, then you should escalate to a person within your company with manufacturing knowledge (component engineer) to validate the concentration at the article level using the articles communicated by your supplier or based on that person’s knowledge. In most cases the false positive will disappear. - Don’t trust REACH CoC declarations your suppliers made in the past or data content providers collected on your behalf are still valid. Most of them evaluated REACH at the component level, just like my friend did. Instruct them to send you new declarations based on the new article interpretation. Of course, you don’t know if they will be correct, but it provides a higher level of due diligence.

Final Thoughts

Just going through this exercise has opened my eyes about how much confusion there still exists in the industry about articles.

I really urge industry bodies to discuss, create, and publish examples, especially for complex components, in the electronics industry.

Besides that, there is a definite need for standards bodies like IPC to define how to communicate articles in, for instance, IPC-1752A declarations.

And finally, software providers must adjust how they validate the 0.1% threshold. To date and to my knowledge, I have not heard any provider communicate that they have modified their software.

Zero Wait-State, the company I work for, has created an add-on to Oracle Agile PLM’s Product Governance and Compliance (PG&C) module to take articles in components into account based on a supplier’s identification of those levels in the product they supply to our clients. This add-on rectifies the fact that the current version of Oracle Agile PG&C does not account for this new definition.

Hopefully the release of the Guidance document will act as a catalyst for these changes to benefit all of us.

Author Dries D'hooghe is the VP of Products and Services for Zero Wait-State and drives the strategy, definition and delivery of PLM products and solutions that enable our customers to implement PLM best practices and processes in a fast and cost effective manner. He also helps customers with the definition and implementation of global environmental best practices into their Product Lifecycle Management (PLM) and Supply Chain Management (SCM) processes and systems. With over 15 years of experience in SCM and PLM in both the US and Europe, Dries navigates customers through the ecosystem of environmental regulatory experts, best practice leaders, and software vendors to achieve concrete and time-driven goals.

Author Dries D'hooghe is the VP of Products and Services for Zero Wait-State and drives the strategy, definition and delivery of PLM products and solutions that enable our customers to implement PLM best practices and processes in a fast and cost effective manner. He also helps customers with the definition and implementation of global environmental best practices into their Product Lifecycle Management (PLM) and Supply Chain Management (SCM) processes and systems. With over 15 years of experience in SCM and PLM in both the US and Europe, Dries navigates customers through the ecosystem of environmental regulatory experts, best practice leaders, and software vendors to achieve concrete and time-driven goals.