Recently, we have been on a bit of a journey due to the maturing and transitioning Product Lifecycle Management (PLM) market. As a long time Oracle partner, we have been a staunch proponent of Agile PLM for many years and a good portion of our work has been deploying Agile PLM and providing complimentary solutions to enhance and automate this technology. Over the past couple of years, Oracle has continued to deemphasize Agile PLM at the expense of their cloud-based offerings. Earlier this year, executives at Oracle told me directly that Oracle Product Development (PD), Oracle’s cloud-based PLM solution, was as functional as Agile Product Collaboration, which is the core module for Agile PLM, so there was no reason for new customers to purchase Agile. I was also told that sales representatives can no longer demonstrate Agile PLM. Obviously, this change in direction has had a bit of a chilling effect on our consulting practice. Fewer new implementations of Agile mean less projects for us. We are still very active with current customers and our State products continue to get a lot of attention, especially our DesignState product. However, cloud PLM is not being adopted as quickly as vendors hoped. In fact, in a recent seminar from CIMdata, they presented their findings, based on responses from the industry, as to why moving to the cloud is slow. Integration and security top the list. At a recent Think Tank we held at PI PLM 2017, we found that the majority of attendees were far more interested in the Internet of Things (IoT) than moving their PLM to the cloud. PLM has always been somewhat of a tough sell and has generally taken a back seat from a priority perspective to Enterprise Resource Planning (ERP) and Customer Relationship Management (CRM). Now IoT has come along and kicked it further down the list… or has it?

Recently, we have been on a bit of a journey due to the maturing and transitioning Product Lifecycle Management (PLM) market. As a long time Oracle partner, we have been a staunch proponent of Agile PLM for many years and a good portion of our work has been deploying Agile PLM and providing complimentary solutions to enhance and automate this technology. Over the past couple of years, Oracle has continued to deemphasize Agile PLM at the expense of their cloud-based offerings. Earlier this year, executives at Oracle told me directly that Oracle Product Development (PD), Oracle’s cloud-based PLM solution, was as functional as Agile Product Collaboration, which is the core module for Agile PLM, so there was no reason for new customers to purchase Agile. I was also told that sales representatives can no longer demonstrate Agile PLM. Obviously, this change in direction has had a bit of a chilling effect on our consulting practice. Fewer new implementations of Agile mean less projects for us. We are still very active with current customers and our State products continue to get a lot of attention, especially our DesignState product. However, cloud PLM is not being adopted as quickly as vendors hoped. In fact, in a recent seminar from CIMdata, they presented their findings, based on responses from the industry, as to why moving to the cloud is slow. Integration and security top the list. At a recent Think Tank we held at PI PLM 2017, we found that the majority of attendees were far more interested in the Internet of Things (IoT) than moving their PLM to the cloud. PLM has always been somewhat of a tough sell and has generally taken a back seat from a priority perspective to Enterprise Resource Planning (ERP) and Customer Relationship Management (CRM). Now IoT has come along and kicked it further down the list… or has it?

There were numerous articles after Jim Hepplemann’s keynote at LiveWorx this year talking about his claim that IoT is PLM. Almost all the articles I read agreed with this assessment in some way. The general thought was IoT extends PLM’s reach by being able to capture the data generated from connected products. Hepplemann went even further at this year's Sales Kickoff meeting claiming IoT, or what he calls the "Industrial Innovation Platform", allows PLM to actually become what it always purported to be. His take is that the traditional PLM focus on Service, Engineering, Operations, Sales and Manufacturing never really materialized. These systems remained silos with some loose integration but PLM rarely attains it’s promised status as the single source of truth. With various versions of the truth floating around in companies, PLM became an archive at best for completed products, but never has achieved its promise as a real-time interface for product development. IoT platforms like ThingWorx enable PLM to achieve its true destiny. It allows a marriage of the digital and the physical so that companies can have a full view of their product development process and make decisions based on real-time data from the field. This architecture also allows information to be collected from systems as well as devices which makes the PLM system far more relevant and powerful since it can collect and classify all the data pouring in from various sources. This capability is one of the key decision criteria that drove our decision to reengage with PTC as a partner. This technology is agnostic and allows us to offer solutions to our existing clients as well as expand into other PLM and CAD platforms.

His take is that the traditional PLM focus on Service, Engineering, Operations, Sales and Manufacturing never really materialized. These systems remained silos with some loose integration but PLM rarely attains it’s promised status as the single source of truth. With various versions of the truth floating around in companies, PLM became an archive at best for completed products, but never has achieved its promise as a real-time interface for product development. IoT platforms like ThingWorx enable PLM to achieve its true destiny. It allows a marriage of the digital and the physical so that companies can have a full view of their product development process and make decisions based on real-time data from the field. This architecture also allows information to be collected from systems as well as devices which makes the PLM system far more relevant and powerful since it can collect and classify all the data pouring in from various sources. This capability is one of the key decision criteria that drove our decision to reengage with PTC as a partner. This technology is agnostic and allows us to offer solutions to our existing clients as well as expand into other PLM and CAD platforms.

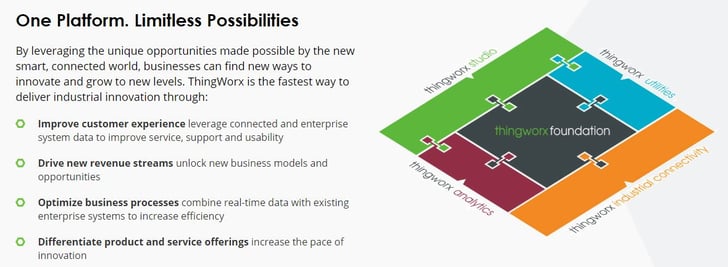

There is a perfect storm of technology that has occurred, driven by cloud development, which enables something far more powerful than just being able to move on-premise software to remote servers. We now have development and data standards coming out of these efforts that can unify multiple systems and enable the flow of data throughout an organization if done properly. The ThingWorx platform from PTC is agnostic and can work with any PLM technology and enables the development of interfaces to both devices and systems. This opens things up quite a bit and makes PLM far more critical in an IoT strategy. All that information must go somewhere and PLM properly configured can accept data from devices and other systems and provide the comprehensive view companies will need to take full advantage of IoT. I would argue that even companies without connected products can benefit from this type of technology. Using IoT platforms to connect systems together and to leverage predictive analytics can enable powerful decision support frameworks that are currently being handled in an ad hoc manner. Most companies have large amounts of data in multiple systems with no way to leverage it to develop better or more profitable products. PLM with IoT can make this happen with proper execution. The key is being able to utilize or quickly develop your interfaces and manage them since changes will be needed frequently due to the dynamic nature of the product development process. This is one of the key features for ThingWorx. It accelerates the development of the interfaces and creates a framework that makes changes and upkeep more feasible.

IoT technologies make PLM a more robust version of itself. Connectivity is enhanced and role-based interfaces can be more easily created and maintained. Information from the products can be real time and more comprehensive. All of this feeds downstream processes in manufacturing and maintenance that will result in more efficient process and better products. PLM has been considered the afterthought of IT systems, but when combined with IoT, it jumps to the forefront as a critical system necessary for companies to fully reach their potential in product development. New, compelling products are the key to company success and having real time access to data from multiple systems accelerates and improves this process. Take a fresh look at your PLM platform and make sure it is ready to leverage IoT. There are many new cloud-based PLM platforms available if your current technology is unable to support these use cases. More than likely, your current PLM is underutilized and can be updated to support IoT for a massive boost to productivity and profits.

We look forward to your comments below.