It is said, if a design flaw is caught and changed during the design cycle it costs $1. The same change made during the approval/release process costs $10. If the change is made during prototype, the cost will be $100. If the flaw makes it to production, the cost is $1000. I don’t know how true this is but I expect it depends on the severity of the design flaw. I suspect that a flaw which makes it to production, if severe enough to require a recall, could generate a change order costing around $10,000 - $100,000.

That sounds like good justification for proper design collaboration.

For support on my thesis, I turned to the internet’s deepest pool of authoritative information, Wikipedia. The topic: Concurrent Engineering. Although the header of this article states, “This article has multiple issues”, there are a few paragraphs that ring true.

- “The basic premise for concurrent engineering revolves around two concepts. The first is the idea that all elements of a product’s life-cycle, from functionality, productibility, assembly, testability, maintenance issues, environmental impact and finally disposal and recycling, should be taken into careful consideration in the early design phases.”

- The second concept is that the preceding design activities should all be occurring at the same time, i.e., concurrently. The idea is that the concurrent nature of these processes significantly increases productivity and product quality. This way, errors and redesigns can be discovered early in the design process when the project is still flexible. By locating and fixing these issues early, the design team can avoid what often become costly errors as the project moves to more complicated computational models and eventually into the actual manufacturing of hardware.

However, it’s not like anyone reading this blog is saying to themselves, “wow, I didn’t know that". And, for the most part, engineers are very aware of the ramifications of a design flaw slipping through the cracks. It is standard practice to involve contributors from manufacturing, quality, compliance, purchasing, marketing and more, in the design process, to ensure that all design considerations are made.

So, my purpose is not to spread the gospel of Concurrent Engineering. That’s been done. I want to focus on the tools that facilitate design collaboration.

If we have all the time in the world to get our design perfect, we would probably use that up and more. But, every project has a deadline and every engineer has a long list of tasks to perform and goals to achieve before the deadline comes. Getting all relevant parties involved in the design process in a timely manner, which is a lot like herding cats. Everyone is busy. So we end up with the design that makes most engineers uncomfortable; the design that is, “good enough”.

Again, this is not news to anyone reading this blog.

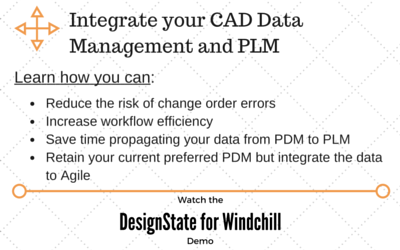

What may, or may not be news to you, is the fact that there are very good tools to facilitate the collaboration process. One such tool is PLM. PLM is (or should be) a collaborative platform accessible by the enterprise that facilitates the definition, and redefinition of a product throughout its lifecycle. Unfortunately, designs are still, typically, not published in PLM until they are very mature. Early designs are kept segregated from PLM to prevent downstream consumers from executing on designs that may not even be considered for release. In many cases, all that gets published to PLM is an attachment of a PDF of a drawing.

But, this doesn’t have to be the norm. PLM Engineering Collaboration tools are available to include designs in the product record from concept through release. A sophisticated security model will ensure that early designs are only seen by the parties contributing to the design process, and not by anyone that might mistakenly execute on it before the design is ready for release. The primary benefit of PLM Engineering Collaboration tools is that the designs are available at the convenience of the contributors, and viewable within the PLM platform. For most purposes, it is no longer necessary to gather people in an engineer’s cube (or on a web conference) to collaborate on designs while they are open in the CAD application. Each contributor can interrogate the design in their own office and capture notes on layers in the viewing application. And since all parties are under the same deadline pressure, it is in everyone’s best interest to contribute early and often.

If you are not linking your CAD applications to PLM with an EC integration, it might be because you had a negative perception of EC from a past experience. I recommend you take a new look at EC. In the 4 years I’ve been at Zero Wait-State, I have seen a steady year-over-year increase in EC adoption, due to continual improvements in the tool’s ability to handle even the most advanced CAD use cases.

An EC integration can get you back some of that time you are so short of, and in the process give you the tools to improve product quality by enabling contributors to collaborate earlier in the design process.

[Edit: Repost from 2015]