Overview

In my previous blog “Compliance Is Complicated! Let’s Start with the Basics”, we discussed PG&C and how it can help with any compliance need a company is facing. Today, I will be sharing some examples and reasons for why I believe that PX automations are both useful and necessary to the successful implementation and execution of your compliance solution. I will cover several important processes found in a compliance implementation, and explain how the PX addresses the challenge while reducing the workload for the compliance user.

Setting Up the BOM for Compliance

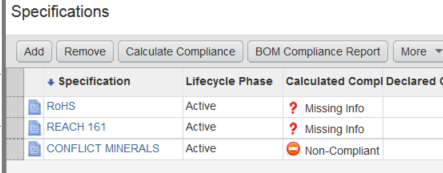

When starting with PG&C, you’ll first create the Specifications library in Agile to track each of the regulations that your company must monitor for a particular product or product line. In order for the PG&C module to begin evaluating the compliance statuses for an item, the specification object has to be added to the top-level assembly, so that the rollup engine can propagate that specification onto each of the sub-components within the Bill of Materials. Depending on the number of top-level assemblies that your company produces, this task can be quite manual and time consuming.

An item can have a number of specifications assigned and calculated for its assembly, but adding them can often be a manual and ambiguous task.

In addition, your products may have different characteristics that affect which regulations need to be interpreted by PG&C. For instance, a piece of electronics has to be monitored for RoHS compliance while a box of test tubes do not. For companies that have a high mix of products, it may be too much effort for the compliance team to add the specifications manually to each BOM, and engineers may also be uncertain about the current compliance environment to accurately determine which specifications to apply.

For this scenario, we have developed a configurable PX that contains a listing of all part types in the system and the specific regulations that we want to associate with each part type. The system can assign the correct specification(s) whenever a part is created, or when a user initiates the task via a workflow status or Actions menu trigger. Specification assignment becomes a breeze, and there is less risk with overlooking an item or seeking out the wrong compliance information.

Importing the Part Compliance Data

A major and important aspect to a compliance solution is how the data will be getting into Agile PLM. Whether it is processed from a data vendor or through the Request For Information (RFI) process with a Supplier/Manufacturer, a PX can be a time-saving and hassle-free method of capturing compliance information for a manufacturer part or item.

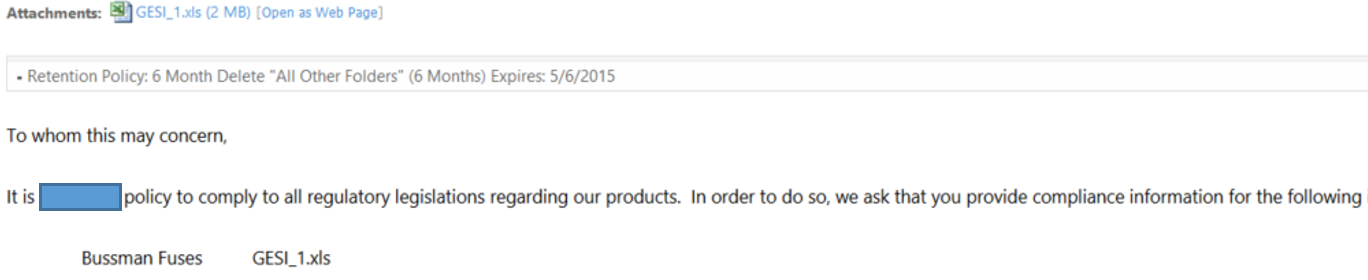

Process Extensions can simplify communication with your suppliers and manufacturers. If the system detects that a new part needs information, it can generate an RFI automatically with the necessary attached forms, notifying you in the process.

In the RFI process, a PX can generate the necessary compliance request forms for each manufacturer part in the AML and email them to the manufacturer’s designated contact. Alternatively, for companies using a data research vendor, the PX can facilitate the data retrieval with the vendor via a web service request and import it directly into Agile. Since the number of parts evaluated can be extensive for larger companies that deal with many manufacturers or suppliers, a PX will efficiently process information in large batches and can provide feedback/errors for any parts needing additional attention.

Automation with compliance data vendors should not be executed without quality standards and the use of due diligence. These data vendors are processing large datasets with hundreds of manufacturing companies, each with thousands of individual parts. It’s only expected that a random part will contain errors or omissions that affects its overall compliance result. And if that part is in your assembly, it will roll up and negatively affect your product’s compliance status. So it’s important to design a release process to review this information as it flows into your Agile system. With the implementation of our LoadState application, you will effectively control and validate the information as its being imported, regardless of the method you choose for receiving it. You should also set up workflow approvals for your Declaration objects, and employ multiple compliance members to check and double check the data before it is released onto your Bill of Materials.

Specific Reporting Beyond Agile Capabilities

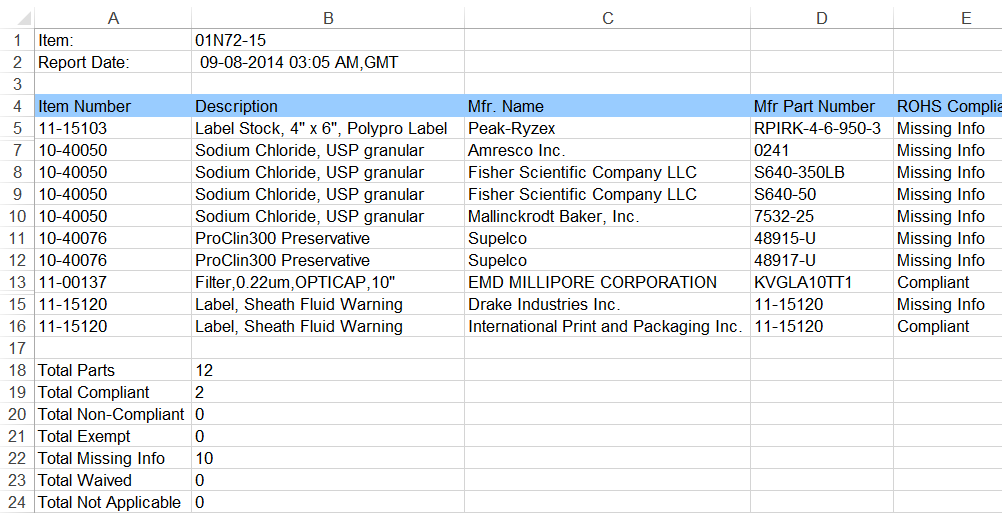

Agile PLM has universal reports that fit a broad need across many companies, but none of them can efficiently interpret and evaluate the specific industrial or environmental regulations. While you may be able to search part attributes and cross reference a variety of data points, you eventually export search results to your desktop and continue your transformations there. But wouldn’t it be nice to start the process with a report that provides meaning and organization in the format you want? A custom PX report can do this, and will greatly help in saving both time and frustrations.

A PX can generate a custom report that displays the compliance breakdown of a product BOM, and it can often pinpoint the source of the problem better than trying to use Agile searches.

We have created numerous reports that tailor specifically to the metrics and layout of each regulation, and can easily create organized result sets using a familiar interface, such as Excel. In this example, the user is able to invoke a compliance report via the Actions menu of any item at any level. The Excel report is generated by the server, and is sent to either the current Agile user or to a pre-determined email address or distribution list. The options are very flexible in this regard, and the whole process takes seconds to run, so you can quickly find the answers you need.

Conclusion

These scenarios only scratch the surface of how PXs can benefit your company and your compliance solution. The possibilities are endless, and these automations can be personalized to incorporate your company’s business logic and constraints. No two companies are the same, so the solutions that are implemented can vary greatly in approach and execution.

Be sure to watch our latest compliance webinar: Accelerating the Compliance Data Collection Process with LoadState 3.0.

You will learn:

- How LoadState can drastically reduce the time to import compliance data into Agile PLM’s compliance module (Agile PG&C) to ensure your products are compliant with RoHS, REACH, Conflict Minerals and other regulations

- How a business user can manage compliance and validation rules in LoadState based on your company’s compliance requirements

- How LoadState will ensure that data imported into Agile satisfies your data collection policy and will reject incomplete declarations

[Edit: Repost from 2015]